TIG Welding with Inverters vs Transformers

Posted by Sean on Feb 13th 2017

A question we often get is "I have an inverter (or transformer) unit, which tungsten should I use?"

The update to our electrode selection chart below should answer that at a glance. The selection of a power source is determined primarily by the metal type and its thickness. Other considerations should be machine size and portability (inverters being smaller/lighter) and energy-efficiency (inverters draw less power). Send us an email if you have questions.

| TIG Welding Tungsten Electrode Selection Chart | |||

| Type | AC/DC | Inverter and/or Transformer | Recommended Usage |

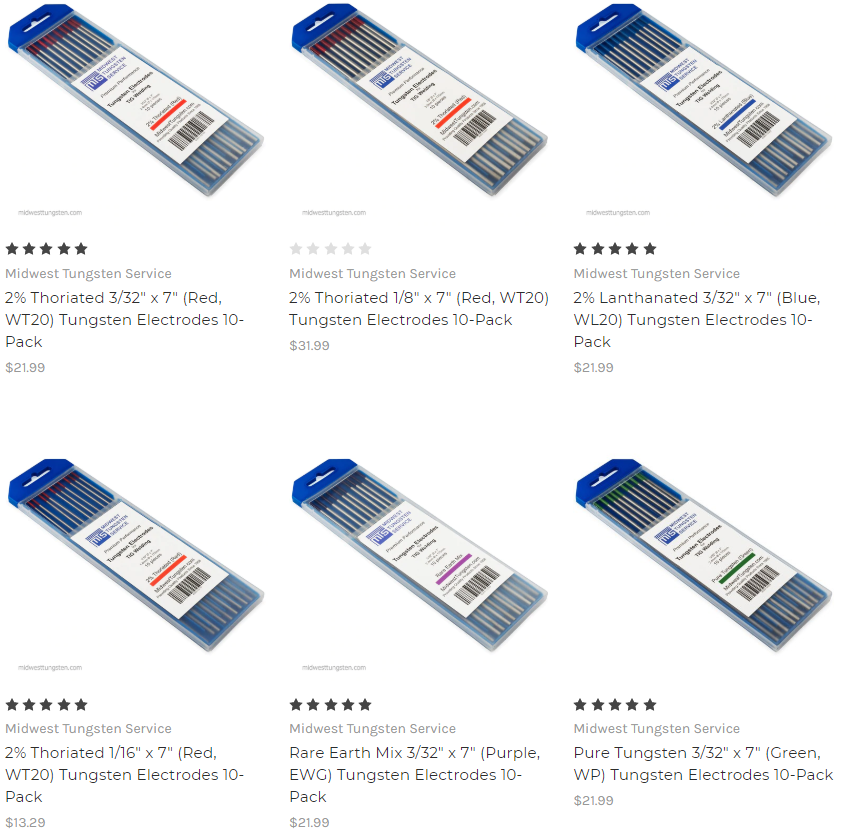

| 2% Thoriated (Red) | DC | Inverter & Transformer | Copper alloys, nickel alloys, titanium alloys, and non-corrosive steels BUY NOW |

| 2% Lanthanated (Blue) | AC & DC | Inverter & Transformer | Aluminum alloys, magnesium alloys, nickel alloys, copper alloys, titanium alloys, low-alloyed steels, and non-corrosive steels BUY NOW |

| Pure Tungsten (Green) | AC | Transformer | Magnesium

alloys and aluminum alloys BUY NOW |

| 2% Ceriated (Grey) | AC & DC | Inverter & Transformer | Titanium alloys, copper alloys, magnesium alloys, aluminum alloys, nickel alloys, non-corrosive steels, and low-alloyed steels BUY NOW |

| 1.5% Lanthanated (Gold) | AC & DC | Inverter & Transformer | Titanium alloys, copper alloys, nickel alloys, and non-corrosive steels BUY NOW |

| Rare Earth Blend (Purple) | AC & DC | Inverter & Transformer | Aluminum alloys, magnesium alloys, titanium alloys, nickel alloys, copper alloys, low-alloyed steels, and non-corrosive steels BUY NOW |

| 0.8% Zirconiated (White) | AC | Inverter & Transformer | Handles higher amp levels for magnesium alloys and aluminum alloys BUY NOW |